Table of Contents

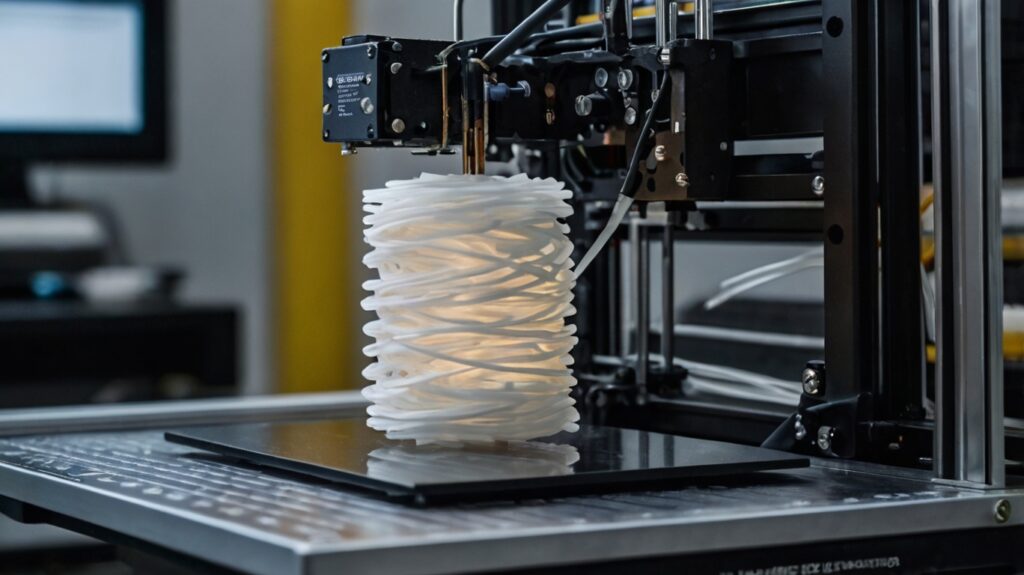

Introduction

Selecting the right filament is crucial for ensuring successful 3D printing outcomes. The filament you choose influences the print quality, strength, flexibility, and finish of your model. With numerous filament types available, each with unique properties, it is essential to understand the nuances of different materials and how they align with your project requirements. Choosing the right filament is not just about aesthetics but also ensuring that the material meets the functional demands of your printed object.

Factors to Consider When Choosing Filament

Application Requirements

- Durability: For functional parts that need to withstand wear and tear, a durable filament like ABS or PETG may be required.

- Aesthetic Quality: If your project prioritizes surface finish, PLA is often favored for its smooth, glossy finish.

- Flexibility: For projects requiring flexible parts, such as gaskets or phone cases, TPU is ideal due to its rubber-like properties.

Physical Properties

- Heat Resistance: Certain filaments, such as ABS and ASA, offer better heat resistance, making them suitable for objects exposed to high temperatures.

- Chemical Resistance: If your print is exposed to harsh chemicals, materials like PETG or ASA are more resistant than others.

- Transparency and Finish: Some filaments, like PETG and PLA, can be printed in transparent or glossy finishes for specific aesthetic needs.

Ease of Printing

- Beginners: PLA is the most user-friendly filament for beginners due to its low printing temperature and minimal warping.

- Advanced Users: ABS or nylon may require a heated bed, higher temperatures, and more precise settings, which are better suited for advanced users.

Printer Compatibility

- Not all filaments are compatible with every printer. It is important to verify whether your printer can handle specific filaments, especially when using exotic materials like nylon, which may require a high-temperature extruder.

Environmental Considerations

- Eco-Friendly Filaments: Filaments like PLA are derived from renewable sources such as cornstarch and are biodegradable, making them a more sustainable option. Other environmentally friendly options include recycled filaments.

Common Types of 3D Printing Filaments

| Filament Type | Properties | Best Used For |

|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, low warping, easy to print | Prototypes, household items, decorative pieces |

| ABS (Acrylonitrile Butadiene Styrene) | High strength, heat resistant, requires heated bed | Functional parts, automotive, industrial applications |

| PETG (Polyethylene Terephthalate Glycol) | Strong, flexible, chemical resistant, food-safe | Mechanical parts, containers, protective covers |

| TPU (Thermoplastic Polyurethane) | Flexible, rubber-like, durable | Phone cases, belts, toys |

| ASA (Acrylonitrile Styrene Acrylate) | UV resistant, weatherproof, durable | Outdoor applications, automotive parts |

PLA (Polylactic Acid)

PLA is one of the most commonly used filaments due to its ease of use and environmental benefits. Made from renewable resources like cornstarch, it is biodegradable and offers a smooth, glossy finish. However, PLA can be brittle and less heat-resistant than other filaments, making it unsuitable for parts exposed to high temperatures.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong, durable material that has higher heat resistance than PLA, making it ideal for functional parts. However, it can be challenging to print with due to warping and the need for a heated bed and controlled environment. It is commonly used in automotive, industrial, and consumer goods applications.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the strength of ABS with the ease of use of PLA. It is resistant to impact, chemicals, and moisture, and can be used for a wide range of applications, including containers and parts that need to withstand mechanical stress.

TPU (Thermoplastic Polyurethane)

TPU is a flexible, rubber-like material that can be used to create bendable and stretchable parts. It’s perfect for items like phone cases, toys, and even functional parts that require elasticity and durability.

ASA (Acrylonitrile Styrene Acrylate)

ASA offers UV and weather resistance, making it the ideal choice for outdoor applications. It has properties similar to ABS but with improved durability when exposed to sunlight.

Latest Trends in 3D Printing Filament (2024)

The 3D printing industry is advancing rapidly, with continuous innovations that enhance print quality, functionality, and material sustainability. In 2024, several key trends are shaping the filament market, driving improvements in both consumer and industrial applications.

Innovations and New Materials

- Composite Filaments: These filaments are infused with various materials to enhance the base filament’s properties. For instance, carbon fiber-infused filaments like CarbonX are gaining traction in 2024 due to their strength and lightweight characteristics. These filaments are particularly beneficial for parts that need to withstand high stress without adding weight, such as aerospace components, automotive parts, and drone frames. Metal-infused filaments, such as stainless steel or bronze composites, allow for the creation of parts with a metallic finish and the potential for post-processing, like polishing or patinas, making them perfect for artistic and functional pieces.

- High-Temperature Filaments: Industrial applications often demand materials that can endure extreme temperatures, chemicals, and environmental stress. Filaments like PEEK (Polyether Ether Ketone) and ULTEM are increasingly being adopted in industries like aerospace, automotive, and medical devices due to their ability to withstand high temperatures (up to 500°F / 260°C) and their exceptional strength-to-weight ratio. These materials were once reserved for specialized applications but are now becoming more accessible to professional users thanks to improvements in extrusion technology.

- Flexible Filaments: As demand grows for more versatile prints, flexible filaments like TPU (Thermoplastic Polyurethane) are becoming more popular. These filaments allow users to print soft, bendable, and stretchable parts that were once difficult to produce with traditional rigid filaments. Applications include gaskets, seals, flexible enclosures, and wearable tech components.

Eco-Friendly Filaments

- Bio-Based and Recycled Materials: With an increasing emphasis on sustainability, manufacturers are producing more eco-friendly filaments that reduce environmental impact. PLA remains the most popular bio-based filament, but newer options like rPLA (recycled PLA) and bio-ABS are gaining attention. These filaments are made from post-consumer recycled plastics, which helps reduce waste and the carbon footprint of 3D printing.

- Recycled Filament Options: In 2024, more brands are introducing recycled filament products that use waste from the plastic industry. Companies like Filamentive and Proto-pasta are creating filaments from recycled plastic bottles, agricultural waste, or ocean plastics. These materials not only support the recycling economy but also deliver high-performance prints while being environmentally conscious.

Advances in Filament Technology

- Low-Warp Filaments: Warping remains one of the biggest challenges in 3D printing. However, in recent years, manufacturers have been producing filaments specifically designed to reduce warping, such as low-warp PLA or PETG. These materials can be printed without a heated bed or with minimal warping, making them ideal for beginner users and those working with larger prints.

- Smarter Filaments: The advent of smart filaments, which come with built-in sensors to detect print quality and adjust settings in real-time, is beginning to take hold. These filaments ensure more consistent results, reduce errors during printing, and are compatible with newer, more advanced 3D printers. They offer potential in applications where precision is critical, such as medical implants or complex mechanical parts.

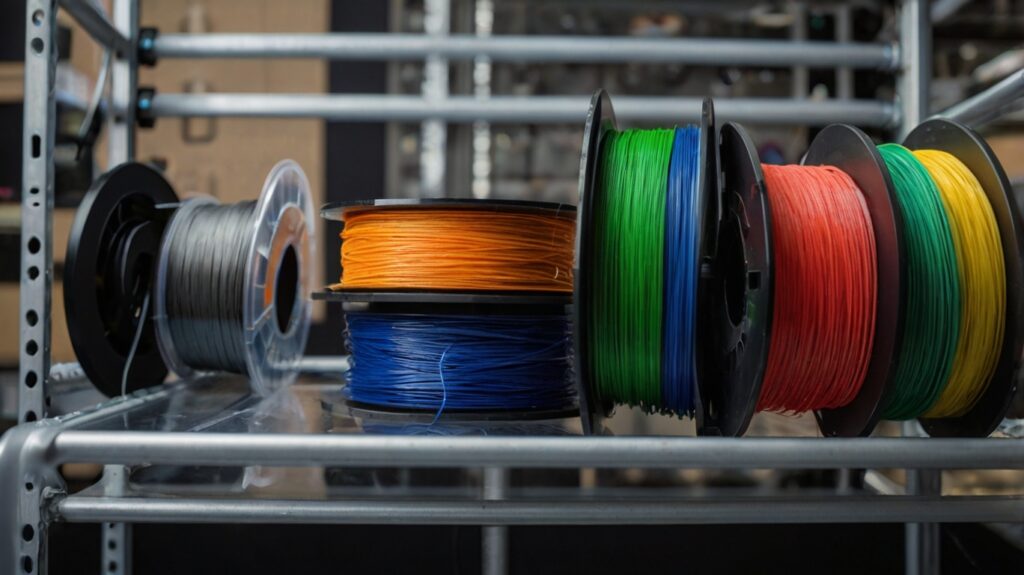

Top Filament Brands to Consider

When selecting filament, the brand can make a significant difference in print quality, consistency, and overall printing experience. Here’s an expanded overview of the top filament brands that have gained a reputation for producing high-quality materials in 2024.

Polymaker

Polymaker is renowned for offering some of the highest-quality filaments on the market, particularly for users seeking reliable and advanced materials. This brand is particularly noted for its consistency, diverse product range, and the use of cutting-edge manufacturing processes. Polymaker’s filaments are favored by hobbyists, professionals, and industrial users alike.

- Key Features:

- PolyLite: A popular, affordable option suitable for beginners. PolyLite PLA and PETG are known for their ease of use, minimal warping, and good surface finish. Ideal for printing prototypes and everyday objects.

- PolyMax: This premium filament offers enhanced mechanical properties, such as higher strength and impact resistance. PolyMax PLA, for example, is twice as strong as standard PLA and is an excellent option for engineering and mechanical applications.

- PolyFlex: A flexible filament line, PolyFlex TPU, provides great elasticity, durability, and the ability to print flexible, stretchable parts with ease, which is ideal for applications requiring flexible gaskets, seals, and wearables.

- PolyCarbonate (PC): Known for its toughness and high-temperature resistance, this filament is ideal for industrial applications where strength, durability, and heat resistance are essential.

- Best for: Users who prioritize quality, consistency, and material diversity. Polymaker is great for both everyday and specialized projects requiring superior strength or flexibility.

MatterHackers

MatterHackers has established itself as one of the largest 3D printing brands in the market, providing a vast range of filaments suitable for hobbyists, educators, and professionals. Their filaments are known for exceptional print quality and value for money. MatterHackers offers both budget-friendly options and high-performance materials.

- Key Features:

- MatterHackers PRO Series: This high-performance filament range offers materials with excellent mechanical properties, such as PRO PLA, PRO PETG, and PRO ABS. These are designed for professional users who require superior strength and durability.

- MH Build Series: This line offers a great balance between quality and price, catering to hobbyists and beginners. Filaments like MH Build PLA and MH Build PETG are easy to print and provide excellent results for general-purpose applications.

- Specialty Filaments: MatterHackers offers a wide selection of specialty filaments, including Nylon, Polycarbonate, and Flexible TPU. These materials cater to advanced users needing filaments with specific properties, such as chemical resistance, flexibility, or high-temperature tolerance.

- MatterHackers Support: Known for its extensive customer service, MatterHackers provides helpful resources and guides for both novice and expert 3D printer users.

- Best for: Users looking for a reliable one-stop shop that offers a diverse range of filaments, including specialty materials for industrial-grade prints, as well as affordable options for beginners.

Hatchbox

Hatchbox is one of the most trusted names in the 3D printing community, offering an extensive selection of filaments that cater to a wide range of users. Known for its high consistency, smooth printing experience, and affordability, Hatchbox is a go-to brand for 3D printing enthusiasts worldwide.

- Key Features:

- Hatchbox PLA: One of the most popular filaments in the market, Hatchbox PLA offers a perfect balance of ease of use and quality. It is known for its excellent adhesion to print beds, low warping, and vibrant colors.

- Hatchbox ABS: This filament is favored for its durability and high heat resistance. ABS is commonly used for applications requiring tough, impact-resistant parts. Hatchbox ABS features good layer bonding and minimal warping with the right bed adhesion.

- Hatchbox PETG: PETG is becoming increasingly popular due to its strength, flexibility, and ability to withstand impact and chemical exposure. Hatchbox PETG is ideal for printing parts that require high mechanical strength and flexibility while being resistant to wear and tear.

- Hatchbox TPU: For users looking for flexible prints, Hatchbox TPU offers a great balance of elasticity and durability, making it ideal for applications requiring flexible, bendable, or stretchable parts like phone cases or seals.

- Best for: Users seeking a reliable and affordable filament brand for general-purpose printing, especially those focused on PLA, ABS, and PETG, which are widely used in a range of applications from hobby projects to industrial prototypes.

eSUN

eSUN is a leading global supplier of 3D printing filaments, renowned for its large range of high-quality products and consistency. The brand has gained popularity for offering some of the most cost-effective filaments without compromising on performance. eSUN is particularly noted for its eco-friendly initiatives and commitment to developing new materials.

- Key Features:

- eSUN PLA+: This is one of the most well-known and widely used filaments by eSUN. PLA+ offers improved strength, toughness, and overall printability over standard PLA. It provides a great surface finish with minimal warping, making it perfect for both beginner and professional users.

- eSUN ABS+: Similar to Hatchbox ABS, eSUN’s ABS+ filament is highly durable, impact-resistant, and suitable for printing strong, functional parts. This filament also has lower warping compared to standard ABS, making it easier to print.

- eSUN PETG: eSUN’s PETG filament has become a favorite for users needing a blend of flexibility and strength. Known for its resistance to impact, chemicals, and high temperatures, eSUN PETG is a go-to filament for printing durable mechanical parts.

- eSUN eFlex TPU: For flexible printing needs, eSUN’s eFlex TPU offers excellent elasticity and resistance to abrasion, making it ideal for printing items like phone cases, gaskets, and wearable devices.

- Eco-Friendly Filaments: eSUN produces eco-friendly filament options, such as ePA (Polyamide) and eSUN recycled PLA, which appeal to environmentally conscious users who want to reduce their carbon footprint while 3D printing.

- Best for: Users who prioritize a wide selection of filaments, especially eco-conscious choices, while still maintaining excellent print quality. eSUN is also a great option for cost-conscious users looking for affordable but reliable filaments.

Prusa Research

Prusa Research, best known for their 3D printers, has also earned a strong reputation for producing high-quality filaments. They offer a variety of filaments that are finely tuned for their 3D printers, although they also work excellently with other brands. Prusa filaments are praised for their consistency and are ideal for users who demand high-quality results.

- Key Features:

- Prusa PLA: Known for its excellent surface quality, adhesion, and ease of use, Prusa’s PLA filaments are designed to produce smooth, high-quality prints. They also come in a wide range of vibrant colors.

- Prusa PETG: This filament is praised for its robustness, chemical resistance, and ease of printing. PETG from Prusa offers a nice balance of flexibility, strength, and printability, making it perfect for durable parts.

- Prusa ABS: For users requiring higher heat resistance and strength, Prusa’s ABS filaments offer great adhesion and durability, especially in industrial applications.

- Prusa PVA: This water-soluble filament is ideal for use in dual extrusion 3D printers for printing support structures. It dissolves easily in water, leaving behind smooth, clean prints.

- Best for: Prusa filaments are ideal for users of Prusa 3D printers but are also compatible with other machines. Their filaments are best for users who prioritize print quality, consistency, and ease of use.

Recommendations for Choosing the Right Filament

Choosing the right filament depends on your specific needs, experience level, and the type of project you are working on. Here’s a step-by-step guide to help you select the ideal filament, along with tips for both beginners and advanced users:

Step-by-Step Approach to Selecting Filament

- Understand Your Project Requirements:

Before selecting filament, ask yourself:- Is the part functional or decorative?

- Will it be exposed to heat, moisture, or chemicals?

- Does it need to be flexible or rigid? Answering these questions will help narrow down your filament choices.

- Printer Compatibility:

Check if your 3D printer is compatible with the filament type you plan to use. Some filaments, like flexible TPU or high-temperature materials like Nylon or PEEK, require specific printer settings or even specific printers capable of reaching higher temperatures. Ensure your printer can handle the required extrusion temperature and bed adhesion settings. - Ease of Printing:

If you’re new to 3D printing, start with easy-to-print filaments like PLA, which requires lower printing temperatures and is less prone to warping. Once you become comfortable with the printing process, you can experiment with more advanced filaments such as ABS, PETG, or even flexible filaments. - Consider Environmental Impact:

If sustainability is important to you, look for filaments made from renewable resources or recycled materials, such as PLA or bio-based filaments. In addition to being more eco-friendly, these filaments are often biodegradable and easier to dispose of responsibly. - Choose Based on Desired Finish and Properties:

If aesthetics are a priority, PLA offers smooth and glossy finishes, whereas filaments like ABS and PETG can provide more matte or textured finishes. For functional parts, prioritize materials like PETG, ASA, or Nylon for their strength, durability, and impact resistance.

Tips for Beginners

- Start with PLA: It’s the most user-friendly filament, offering minimal warping and great print quality. It’s ideal for most home 3D printing projects, from models to prototypes.

- Use a heated bed: This helps prevent warping and promotes better adhesion, especially when printing with materials like ABS or PETG.

Tips for Advanced Users

- Experiment with composites: Try filaments infused with carbon fiber or metal to create lightweight yet strong parts.

- Handle high-temperature materials with care: Filaments like Nylon, PEEK, or ULTEM require high extrusion temperatures, so ensure your printer is capable of handling these materials safely.

Conclusion

Mastering filament selection is essential for achieving the best results in 3D printing. By considering factors like application, physical properties, printer compatibility, and environmental impact, you can make informed decisions that will help you print high-quality, functional parts. Whether you’re a beginner or an experienced user, understanding the differences between filaments will give you the edge to bring your ideas to life with precision and reliability.

Also Read : “Functional Mechanical Gears in 3D Printing: Design, Materials, and Techniques”

[…] Also Read : “Mastering 3D Printing: Selecting the Best Filament for Your Needs” […]