Table of Contents

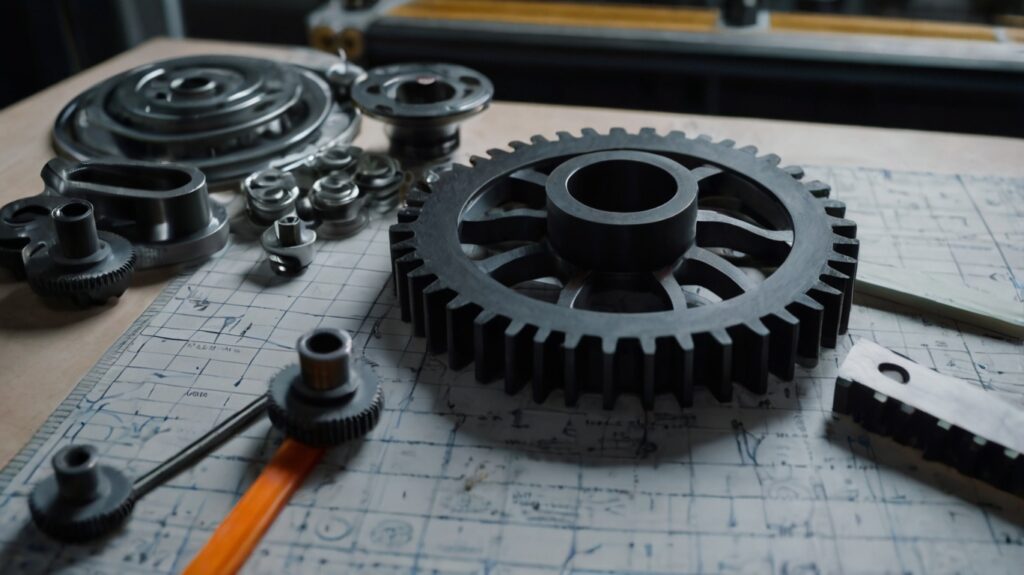

Introduction to Mechanical Gears in 3D Printing

3D printing has transformed modern manufacturing, enabling rapid prototyping and customization of complex components. Among its many applications, the creation of functional mechanical gears stands out as an area of immense potential. Gears are essential in countless machines and devices, but designing and producing them via 3D printing requires meticulous attention to design principles, material selection, and printing techniques.

Design Considerations for 3D-Printed Gears

The design of 3D-printed gears requires precision and careful planning to ensure optimal performance, longevity, and durability. Below are key considerations that contribute significantly to achieving functional and reliable gears:

Tooth Design and Load Distribution

- Optimizing Tooth Size: Larger teeth are particularly suitable for small gears as they help prevent weak or fragile sections. Avoid making teeth smaller than 0.4 mm when using a standard 0.4 mm nozzle to ensure robust structural integrity. Additionally, increasing the size of individual teeth in relation to the gear’s diameter can enhance their overall resilience.

- Load Distribution: Ensuring a higher number of teeth are in contact during operation allows for better load distribution, reducing the risk of gear failure and minimizing wear over time. Chamfering and filleting the edges of the teeth can further reduce stress concentrations, leading to improved durability and smoother gear operation, even under heavy loads.

Gear Pairing

- Avoiding Divisible Tooth Counts: Gears paired with divisible tooth counts, such as a 12-tooth gear with a 24-tooth gear, can lead to uneven wear patterns and shorter lifespan. Instead, selecting non-divisible combinations, like pairing a 12-tooth gear with a 25-tooth gear, ensures that the same teeth do not meet repeatedly, promoting even wear and extending the gear’s lifespan.

- Backlash Management: Incorporating a slight amount of backlash during the pairing of gears can prevent binding, enhance smooth motion, and account for material expansion due to environmental factors like temperature changes.

Tolerance and Fit

- Alignment and Clearance: Proper alignment of gear axes is critical to ensuring smooth operation. A clearance range of 0.2-0.5 mm between meshing gears is generally recommended to prevent binding while maintaining efficient torque transfer.

- Oversized Axle Holes: Slightly oversized axle holes, typically around +0.1 mm, help facilitate easy assembly, reduce friction during operation, and accommodate minor inaccuracies in the printing process. This adjustment ensures smooth rotation and proper engagement of the gears during use.

Material Selection for 3D-Printed Gears

The choice of material significantly impacts the performance and longevity of 3D-printed gears. Below is an expanded overview of common materials and their properties, including practical considerations for their use:

| Material | Advantages | Limitations | Best Use Cases |

|---|---|---|---|

| Nylon | High strength, flexibility, low friction, excellent inter-layer adhesion | Requires controlled humidity, absorbs moisture, demands heated bed | High-stress and high-torque applications |

| PLA | Easy to print, highly rigid, biodegradable | Low heat resistance, brittle under stress | Prototypes and low-stress applications |

| ABS | Better heat resistance, balance of flexibility and strength | Warping during printing, emits fumes, requires post-processing | Moderate-stress and high-temperature environments |

| PETG | Durable, impact-resistant, good balance between flexibility and strength | Excessive flexibility, reduced force transfer | General-purpose or less precise gears |

Each material has distinct advantages and limitations that make it more or less suitable for specific use cases. By carefully assessing the operating conditions and performance requirements of your gears, you can select the material that best fits your needs.

Printing Techniques for Functional Gears

The success of 3D-printed gears hinges on employing meticulous and precise printing techniques. Following these guidelines ensures optimal performance, durability, and reliability of your gears:

Infill Density

- Use a high infill percentage (60%-100%) to significantly enhance the strength and durability of the printed gears. A solid infill helps the gears withstand intense mechanical stresses and ensures they perform well under load-bearing conditions. For highly demanding applications, a 100% infill is particularly beneficial as it minimizes internal weaknesses and maximizes structural integrity.

Layer Height

- Opt for smaller layer heights (0.1 mm or less) to achieve finer details and smoother gear surfaces. This level of precision improves the meshing accuracy of the gear teeth, which is critical for seamless operation. Additionally, smaller layer heights contribute to reducing surface irregularities, making post-processing less intensive and enhancing overall gear functionality.

Post-Processing

- Post-processing is crucial to refine the gear’s surface and ensure precise assembly. Smooth gear teeth by sanding, chemical treatment, or other finishing methods to remove imperfections caused by the layer-by-layer printing process. This is particularly important for FDM (Fused Deposition Modeling) prints, which may exhibit rough surfaces that can hinder gear meshing. Proper adjustments to fitments during post-processing further guarantee tight and accurate tolerances.

Iterative Testing

- Print test gears to evaluate their fit, performance, and durability before finalizing complex designs. Iterative testing allows you to identify and address potential issues, such as improper tolerances or alignment problems, early in the process. Each iteration provides valuable feedback, enabling you to refine the design and printing parameters to achieve optimal results. This approach is especially useful when working on innovative or customized gear systems.

Applications of 3D-Printed Gears

The versatility of 3D-printed gears makes them suitable for a wide range of applications across various fields and industries, showcasing their adaptability and innovative potential:

Speed Reducers

- Commonly used in small electric motors or hand-cranked devices where mechanical advantage is essential. These 3D-printed gears are particularly valuable in applications that require compact and lightweight components, making them ideal for portable devices or experimental setups. Additionally, the ability to rapidly prototype and test these gears enables quicker iterations and improvements in performance.

Custom Projects

- Perfect for hobbyists, engineers, and designers looking to create bespoke mechanical systems or prototypes without the cost and time constraints of traditional manufacturing. 3D printing allows for unprecedented levels of customization, enabling users to experiment with unconventional gear shapes, sizes, and configurations tailored to specific tasks. This capability is especially useful in robotics, automation, and art installations, where creativity and functionality merge.

Educational Tools

- Useful in academic settings to demonstrate mechanical principles and gear dynamics. 3D-printed gears provide an affordable and interactive way for students to explore concepts like torque, force transfer, and motion mechanics. Educators can use these tools to create hands-on experiments, allowing learners to better understand gear operation and design. This accessibility to practical learning aids is transforming how engineering and physics are taught in classrooms.

Challenges and Solutions

Despite its advantages, 3D printing of gears presents certain challenges that must be addressed to ensure optimal functionality and performance:

Material Limitations

- Challenges: Certain materials may lack the necessary durability or flexibility to handle specific mechanical stresses, which can limit their application. For instance, low-stress environments might work well with PLA, but more demanding applications require advanced materials like nylon.

- Solution: Select materials carefully based on the intended use case. Nylon is ideal for high-stress applications due to its strength and flexibility, while PLA is better suited for prototypes or less demanding conditions. For projects with higher thermal requirements, ABS can serve as a reliable alternative.

Precision Requirements

- Challenges: Achieving the accuracy needed for smooth gear operation can be difficult due to limitations in printer calibration, nozzle size, or design flaws. Poorly aligned or mismatched gear teeth can lead to inefficiencies or failures.

- Solution: Use high-quality 3D printers capable of fine-tuned settings and consistent output. Incorporate smaller layer heights and conduct regular calibration checks to maintain dimensional accuracy. Leveraging advanced software for detailed modeling can further enhance precision.

Surface Finish

- Challenges: The layer-by-layer nature of 3D printing often leaves surface irregularities that can impede smooth gear meshing or cause increased wear over time. Rough surfaces also contribute to higher friction and reduced efficiency.

- Solution: Employ post-processing techniques to refine the surface finish. Sanding, chemical smoothing, or applying coatings can significantly improve the quality of the gear teeth, allowing for better engagement and longer operational life. Testing post-processed gears for fit and performance ensures that these enhancements meet functional requirements.

Conclusion

3D printing has opened new horizons in the design and production of functional mechanical gears. By adhering to design principles, selecting appropriate materials, and employing precise printing techniques, users can create durable, high-performance gears tailored to specific needs. With practice and experimentation, the potential for innovation in this field is boundless.

FAQs

What is the best material for 3D-printed gears?

Nylon is considered the best material for 3D-printed gears due to its strength, flexibility, and low friction properties. It is ideal for high-stress applications.

How can I improve the durability of 3D-printed gears?

Focus on optimizing tooth design, using high infill density (60%-100%), and selecting durable materials like nylon. Post-processing techniques can also enhance durability.

Can PLA be used for functional gears?

Yes, PLA can be used for low-stress applications. However, it is not suitable for high-temperature environments as it softens at around 60°C.

What is the recommended clearance for meshing gears?

Maintain a clearance of 0.2-0.5 mm between meshing gears to prevent binding and ensure smooth operation.

Why is iterative testing important in 3D printing gears?

Iterative testing allows you to evaluate fit and performance, identify potential issues, and make necessary adjustments before finalizing the design.

[…] Also Read : “Functional Mechanical Gears in 3D Printing: Design, Materials, and Techniques” […]