Table of Contents

Introduction

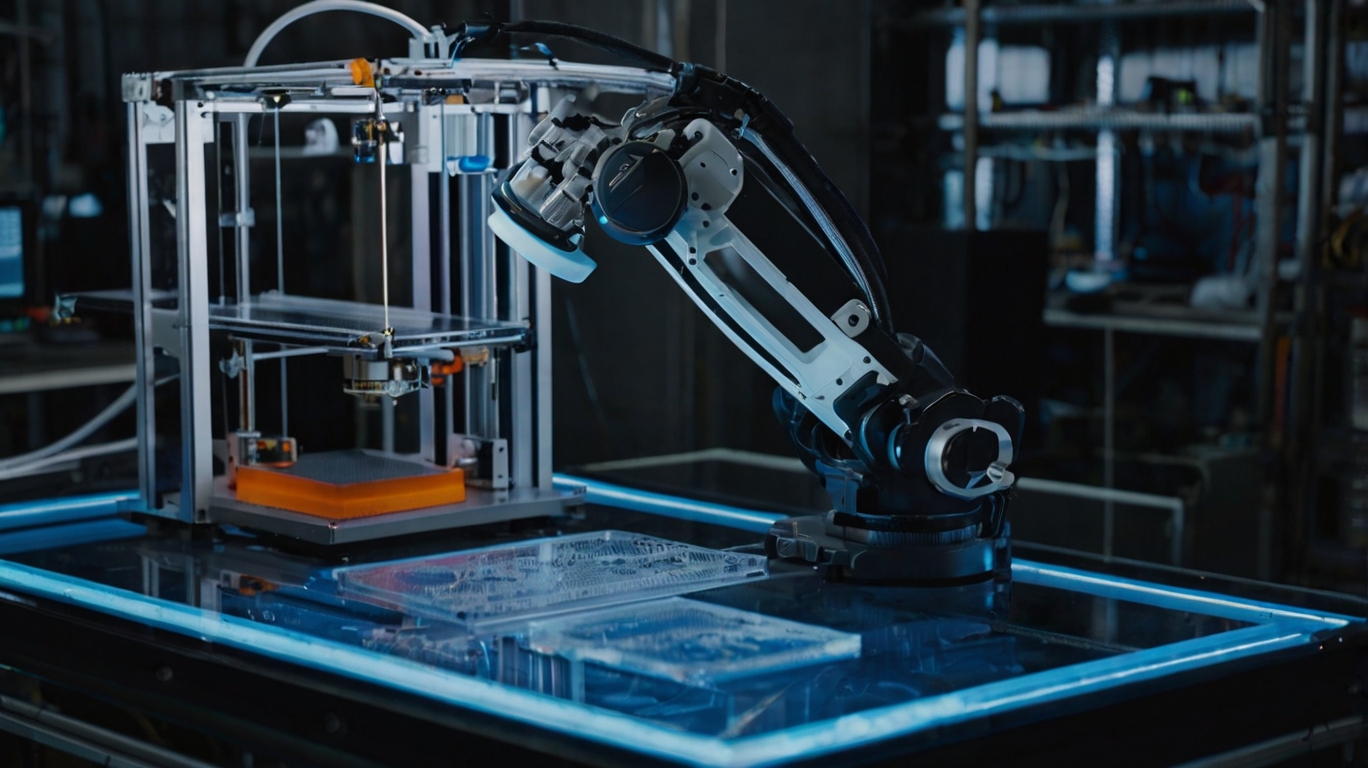

3D printing has revolutionized manufacturing, design, and prototyping across various industries. By transforming digital designs into physical objects, it has unlocked opportunities for innovation and customization. However, with multiple 3D printing techniques available, choosing the right one is essential to achieve optimal results.

The three most commonly used 3D printing methods are FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each has unique capabilities, materials, and applications, making the selection process crucial for project success.

This article dives into the specifics of FDM vs SLA vs SLS comparing their strengths and weaknesses to help you make an informed decision.

What is FDM (Fused Deposition Modeling)?

FDM is one of the most widely used and accessible 3D printing technologies, recognized for its affordability and versatility. It has revolutionized prototyping and small-scale manufacturing by enabling individuals and businesses to quickly produce functional models and parts. Its popularity stems from the use of cost-effective materials and the simplicity of the printing process, making it a go-to choice for beginners and professionals alike.

How does it work?

FDM involves heating a thermoplastic filament and extruding it through a nozzle to build layers of the object on a build platform. This layer-by-layer process creates the final structure.

Common Materials Used

- PLA (Polylactic Acid)

- ABS (Acrylonitrile Butadiene Styrene)

- PETG (Polyethylene Terephthalate Glycol)

- TPU (Thermoplastic Polyurethane)

Applications

FDM is widely used for:

- Prototyping and product development

- Educational purposes

- Manufacturing jigs and fixtures

- Creating affordable models and functional parts

What is SLA (Stereolithography)?

SLA is a groundbreaking 3D printing technology renowned for its ability to produce highly detailed and smooth models. It is widely used for applications that demand precision and intricate designs, making it an excellent choice for industries like dental, jewelry, and artistic prototyping.

How does it work?

SLA uses a UV laser to cure liquid resin into solid layers. The laser selectively hardens parts of the resin, building the object layer by layer.

Common Materials Used

- Standard resins (for general use)

- Tough resins (for durable parts)

- Dental and medical resins

- Flexible resins

Applications

SLA is ideal for:

- High-detail prototypes

- Jewelry design

- Dental molds and medical devices

- Miniatures and artistic creations

What is SLS (Selective Laser Sintering)?

SLS is a powerful and versatile 3D printing technology widely used for producing durable and functional parts. It excels in creating complex geometries without the need for support structures, making it an excellent choice for industrial applications such as aerospace, automotive, and medical devices.

How does it work?

SLS uses a high-powered laser to sinter powdered material, fusing it into solid layers. Unlike FDM and SLA, SLS does not require support structures, as the surrounding powder provides support during printing.

Common Materials Used

- Nylon (Polyamide)

- Polypropylene

- TPU (for flexible parts)

- Composite powders (e.g., nylon with glass or carbon fibers)

Applications

SLS is commonly used for:

- Functional prototypes

- End-use parts

- Aerospace and automotive components

- Complex geometries and lattice structures

Comparison of FDM, SLA, and SLS

| Feature | FDM | SLA | SLS |

|---|---|---|---|

| Technology and Process | Extrusion of heated filament | Laser curing of liquid resin | Laser sintering of powdered material |

| Material Compatibility | Limited to thermoplastics | Wide range of resins | Versatile powders like nylon |

| Surface Finish and Detail | Moderate, visible layer lines | Excellent, smooth surfaces | Good, slightly grainy texture |

| Durability and Strength | Suitable for functional parts | Brittle, not ideal for high-stress use | Strong and durable |

| Cost Considerations | Low initial and material costs | Moderate to high material costs | High equipment and material costs |

| Speed of Production | Moderate | Slower for large models | Fast for multiple parts |

| Ease of Use | Beginner-friendly | Requires post-processing | Advanced, industrial use |

Pros and Cons of Each Technique

Advantages and Disadvantages of FDM

Advantages:

- Affordable and accessible

- Wide range of thermoplastic materials

- Easy to use for beginners

Disadvantages:

- Limited resolution and surface finish

- May require post-processing for smoothness

- Weaker layer adhesion compared to other methods

Advantages and Disadvantages of SLA

Advantages:

- Exceptional surface detail and precision

- Ideal for intricate designs

- Wide variety of resins

Disadvantages:

- Resin can be costly and messy

- Brittle parts unsuitable for heavy loads

- Requires extensive post-processing

Advantages and Disadvantages of SLS

Advantages:

- No need for support structures

- Strong, functional parts

- Excellent for complex geometries

Disadvantages:

- Expensive equipment and materials

- Grainy surface finish may require smoothing

- Industrial-level expertise needed

When to Choose FDM, SLA, or SLS

FDM:

- Best for budget-friendly, functional prototypes and models

- Ideal for beginners or small-scale projects

SLA:

- Perfect for highly detailed, smooth prototypes and artistic applications

- Great for dental, jewelry, and medical industries

SLS:

- Suitable for industrial-grade, durable parts and complex designs

- Preferred for aerospace, automotive, and high-performance applications

Conclusion

Choosing the right 3D printing method depends on your application, budget, and material needs. While FDM offers affordability and accessibility, SLA excels in precision and detail. SLS stands out for its strength and versatility in demanding applications.

By understanding the strengths and limitations of each technique, you can select the one that aligns with your project goals and deliver outstanding results.

FAQs

What are the main differences between FDM, SLA, and SLS?

FDM uses thermoplastic filaments, SLA uses liquid resin cured by lasers, and SLS uses powdered material sintered with lasers. Each differs in cost, precision, and applications.

Which technique is best for beginners?

FDM is the most beginner-friendly due to its affordability, ease of use, and wide availability of materials.

Are SLA prints stronger than FDM prints?

SLA prints are more precise but typically more brittle than FDM prints, which are better for functional parts.

What materials can be used in SLS printing?

Common SLS materials include nylon, polypropylene, TPU, and composite powders like glass-filled or carbon-filled nylon.

How do I decide which 3D printing method to use?

Consider your project’s requirements, including budget, detail, strength, and application. Choose FDM for affordability, SLA for precision, and SLS for strength and complexity.

Discover the Key Differences Between FDM, SLA, and SLS 3D Printing Techniques

[…] Explore a deeper comparison of 3D printing technologies with our article on FDM vs. SLA vs. SLS: Whi… […]

[…] Detailed Comparison of FDM vs SLA vs SLS […]

[…] Also Read: FDM vs SLA vs SLS: Which 3D Printing Technique Suits Your Needs? […]